Kampi ehf is a local company we students regularly come across when passing by the company’s docking freezing trawler ‘Ísbjörn ÍS-304’. And then there is this curious question of how the main ingredient of a tasty prawn cocktail ends up being the way we find it: cooked, peeled and fresh.

We decided to find out more about the trawler and the process of undressing a prawn and arranged a company visit with Salmar Jóhansson, the Quality Manager of Kampi ehf. This started by Salmar giving a lecture to us at the Uni Center, introducing into the company’s history and technology and explaining health and safety issues in preparation for our site visit.

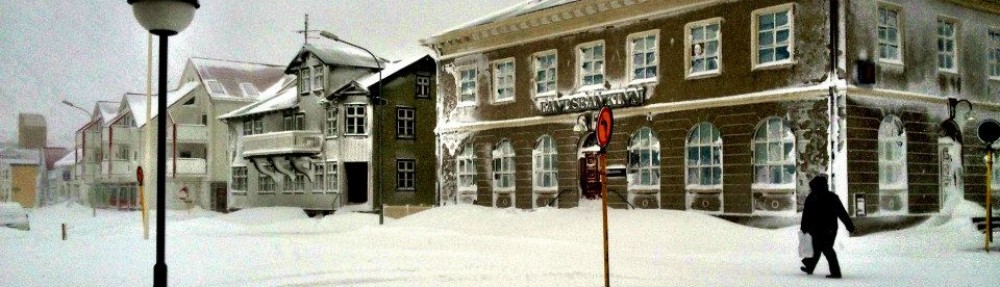

Prawns were first caught in Iceland around 1930 and Ísafjörður was the first town to start processing prawns in Iceland. Its main representative in that respect nowadays is Kampi ehf, an experienced and leading prawn factory and prawn processing specialist. Besides catches from the Ísbjörn ÍS-304 the factory receives further input from Gunnbjörn IS and Valbjörn IS. Those two trawlers belong to Birnir ehf, the biggest shareholder of Kampi, who catches fresh prawns for Kampi from February to end of October each year.

Kampi produces high quality products with maximum supervision from the quality management team, its customers own auditing team and independent trusted sources – which we could witness on site. Besides, Kampi is an environmentally aware producer. Two examples for this are the company’s recent switch from oil to electricity (remember the Icelandic context!) and the processing of shell waste into prawn meal.

Takk fyrir, Salmar Jóhansson, for having provided us with this exciting opportunity! (katrin krzewina)

- Photo Credit: Kampi ehf

- Photo Credit: Kampi ehf

- Photo Credit: Chelsea Boaler

- Photo Credit: Chelsea Boaler

- Photo Credit: Kampi ehf

- Photo Credit: Kampi ehf

- Photo Credit: Chelsea Boaler

- Photo Credit: Matija Drakulić

- Photo Credit: Chelsea Boaler

- Photo Credit: Chelsea Boaler

- Photo Credit: Kampi ehf

- Photo Credit: Chelsea Boaler

- Photo Credit: Chelsea Boaler

- Photo Credit: Kampi ehf

- Photo Credit: Kampi ehf

- Photo Credit: Matija Drakulić